Quality Assurance

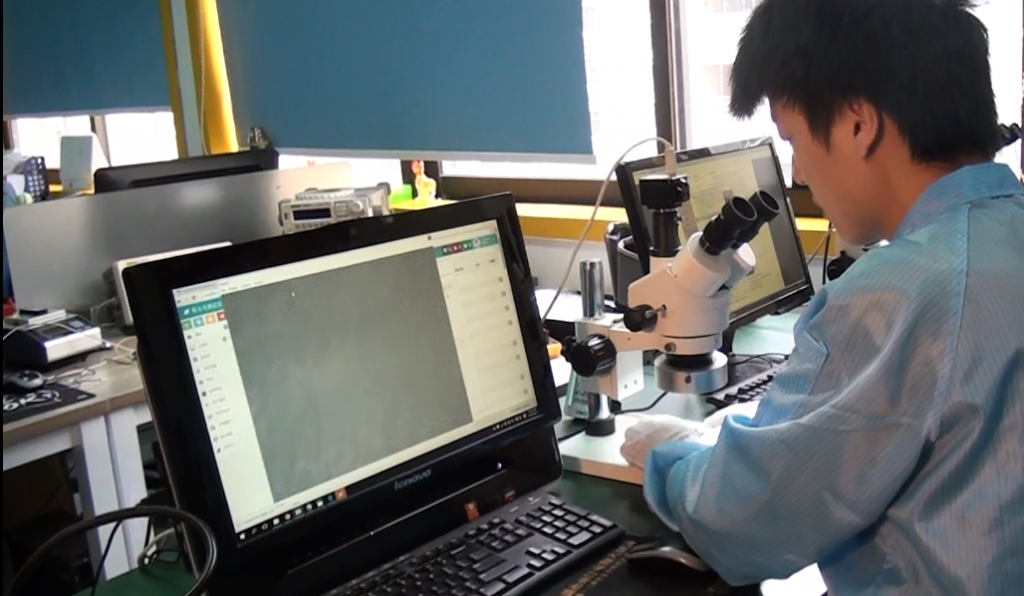

test laboratory

A rigorous quality inspection process is a core part of CHIPS CENTER’s quality control system. To ensure the integrity and profitability of our customers, we have developed each inspection step to ensure practical and effective implementation. Our state-of-the-art inspection process, specialised inspection equipment and most importantly – experienced QCs with a professional and responsible work ethic – ensure that our customers receive world-class quality goods.

For over 20 years, Fusion Worldwide has set the standard for quality. Our team is committed to delivering parts that meet our customers’ requirements. In addition, we go above and beyond to ensure that your electronic components are certified for form, fit and function.

Strict inspection process

Step 1 Exterior Inspection

For all incoming goods, we will execute appearance inspection and make detailed inspection records.

- Manufacturer, manufacturer’s material number, quantity, date of production and environmental standards inspection.

- Packaging inspection, whether the packaging is intact/complete, whether the packaging material meets the requirements of the corresponding MSL standards.

- Screen printing (Marking) inspection, consistency inspection.

- Material appearance inspection, dust condition

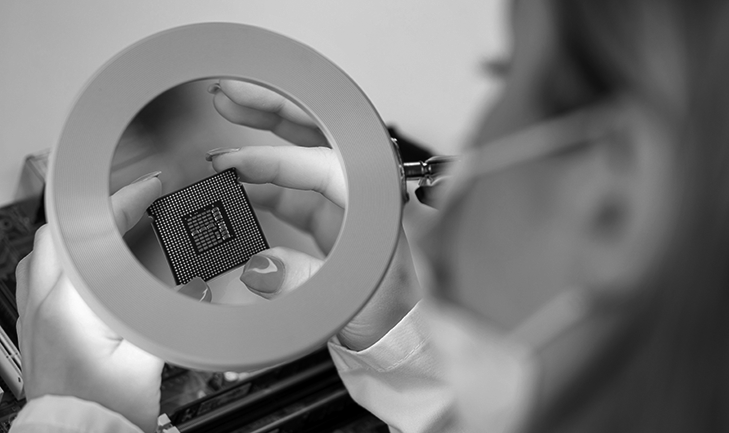

Step 2 Engineer Review

All materials that are found to be doubtful in the appearance inspection, or materials that are not supplied by “Tier 1 suppliers” in the supplier channel of the system, should be re-inspected by engineers.

- Review Appearance Inspection Process

- Black top inspection, acetone test, thermo-chemical reaction test.

- PIN pin refurbishment inspection, pin pin deformation, pin pin whether there are signs of oxidation, flat consistency test

- Package size inspection

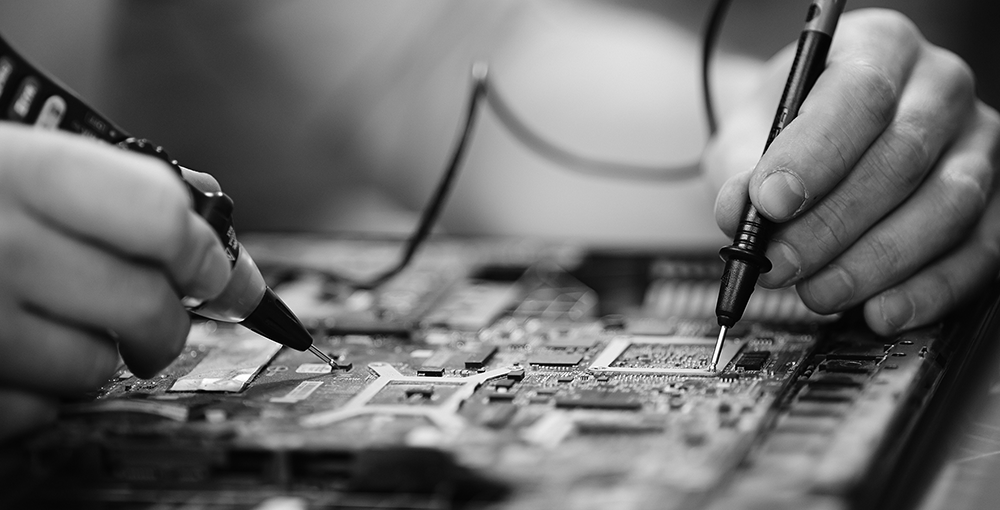

Step 3 quality testing

- Quality Testing Solderability Testing

- D-CAP Analysis

- Anatomical Analysis

- Electrical Conformance Testing

- Room temperature critical function test

- Authoritative test and analysis report

Supplier Management

CHIPS CENTER has established an independent procurement supply chain system through more than 10 years of distribution experience. The company has established a strong supplier grading system, which contains detailed information of more than 4000 suppliers. Every quarter, we re-audit all suppliers and strictly enforce the tier system.

Tier 1 (Tier 1 Suppliers)

Distributor, original manufacturer

Tier 2 (Tier 2 Suppliers)

OEM, ODM, EMS factories

Tier 3 (Tier 3 Suppliers)

Suppliers with annual turnover of $60M or more, with third party certifications (ERAI, IDEA, ISO)

Tier 4 (Tier 4 Suppliers)

Suppliers with an annual turnover of $30M or more and have been in the component supply industry for more than 10 years.

Tier 5 (Tier 5 Suppliers)

Other suppliers (including new suppliers)

CHIPS CNETER is your best source for quality electronic components.

We may have the product model you need, please fill out the enquiry form and our sales representative will contact you immediately.